![]() Price:

Negotiable

Price:

Negotiable

![]() Model:

YS-188X

Model:

YS-188X

![]() Speed:

30-60BAGS/MIN

Speed:

30-60BAGS/MIN

![]() Bag Size:

Inner bag size: Length (L): 70-75 mm Width (W): 90-100 mm Outer bag size: Length (L): 120 mm Width (W): 100 mm

Bag Size:

Inner bag size: Length (L): 70-75 mm Width (W): 90-100 mm Outer bag size: Length (L): 120 mm Width (W): 100 mm

![]() Pack Weight Range:

Pack Weight Range:

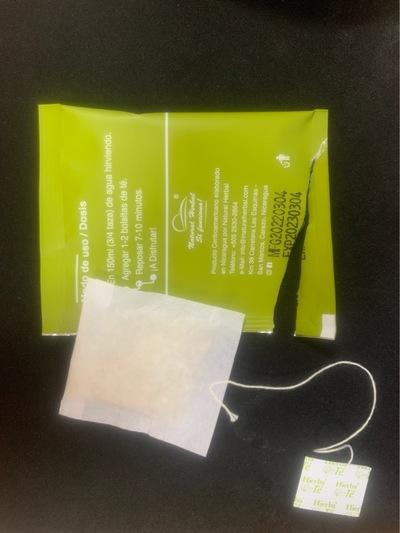

![]() Film Material:

Composite membrane, nylon, corn fiber, drip coffee membrane.

Film Material:

Composite membrane, nylon, corn fiber, drip coffee membrane.

![]() Gas Source:

≥0.6m³/ min

Gas Source:

≥0.6m³/ min

![]() Bag Shape:

Three sides sealing

Bag Shape:

Three sides sealing

![]() Machine Size:

1203 * 809 * 2141 mm

Machine Size:

1203 * 809 * 2141 mm

![]() Weight:

660

Weight:

660

![]() Certification:

CE,ISO,SGS

Certification:

CE,ISO,SGS

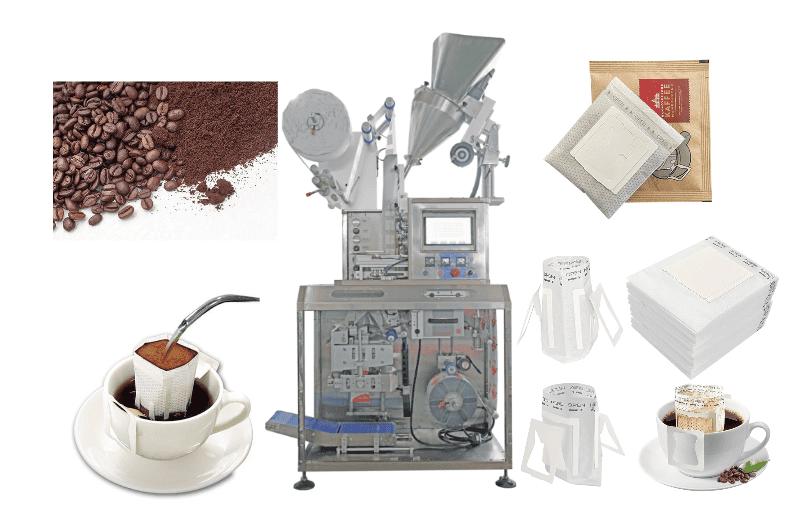

YS-188X Drip coffee packing machine is not only suitable for the packaging of drip coffee, but can also be widely used in the inner and outer bag packaging of other similar products, such as tea, herbal drinks, etc., to meet the needs of various market segments.

| YS-188X drip coffee packaging machine |

|

Measuring Scope |

1 - 15 g |

|

size |

Inner bag size:( L ) :70-75 mm ( W ) :90-100 mm

Outer bag size:( L ) :120 mm ( W ) :100 mm

|

|

Packing Speed |

30-60 bags/min |

|

Dimension ( L * W * H ) |

1203 * 809 * 2141 mm |

|

Weight |

660 kg |

|

Total Power |

AC220V / 50Hz / 3.7kw |

|

Gas source |

≥0.6m³/ min |

Application: YS-188X is not only suitable for the packaging of drip coffee, but can also be widely used in the inner and outer bag packaging of other similar products, such as tea, herbal drinks, etc., to ...

Snus nicotine pouch machine Suitable for small particle packaging such as snuff, broken tea, desiccant, etc....

YS-ZF90 The Pyramid tea bag machine has a precise weighing system, ideal for use (such as black tea, green tea, scented tea, loose tea, etc.) and can be used in combination with outer packaging machines and b...

Tea might be considered an everyday product, but it presents tough challenges when it comes to packaging. Our coated paper for tea bag envelopes offers exceptional features for superior packaging that preserv...

YS-188X drip coffee packaging machine is an efficient, fully automated drip coffee packaging machine designed to meet the needs of the modern coffee market. The equipment can not only accurately produce drip ...

The pyramid tea bag is beautifully shaped and I am very satisfied. Thanks Ethan2024-08-09

Efficient and Reliable Our tea bag packaging machine has been incredibly efficient and reliable, meeting our production demands effortlessly.2024-08-09

The inner and outer bags are packed perfectly.2024-08-09

Cost-Effective Solution Investing in this machine has proven to be a cost-effective solution for scaling our tea production operations.2024-08-09